Product Overview

Hi-Volume production for textile & apparel & promotional goods use.

Printhead: EPSON i3200 * 4

Productivity: 180 sqm/h

Ink Set: CMYK

Drop Volume: 2.5pl

Print Size: 3200mm

Resolution: 3200dpi

Ink: Dye Sublimation, Water base.

Specification (Machine Details)

| X E N O N S | ||||

| Models | X4E-320 | |||

| Print Head | EPSON i3200, DX5 | |||

| Number of print heads | 2/4 | |||

| Fabric | Width | 3200 mm (126 Inch) | ||

| Thickness | Maximum 3.00 mm | |||

| Roll Outer Diameter | Maximum 3200 mm (126 Inch), 1270mm(50 inch)*2 | |||

| Roll Weight | Maximum 100 Kg | |||

| Core Diameter | 76.2mm (3 in)/50.8mm (2 in) | |||

| Types | Fabric (Solvent Based), SAV, PVC Banner, Backlit Film, Window Film,transfer paper and many more | |||

| Printing Width | Maximum 3200mm (126 in) | |||

| Inks | Types | Eco solvent/Dye Sublimation/Water Base | ||

| No. of Color | 4 Colors (CMYK)/6Colors (CMYK+LM LC ) | |||

| Ink Capacity | 3.5L (± 100 ml) | |||

| Printing Resolution (dots per inch) | Maximum 3200 dpi | |||

| Media take-up system | Auto-Feeding system and take-up system | |||

| Interface | High Speed USB-3.0/ Lan port | |||

| Power-saving feature | Automatic sleep feature | |||

| Power supply | Voltage and frequency | |||

| AC 220 V ± 10%, 50/60 Hz | ||||

| Required power capacity | ||||

| Maximum 35A (Printer 15A, Heater 25A) | ||||

| Printer Dimensions | Machine(L*W*H): 4750*1100*1580mm | |||

| Package(L*W*H): 4940*1095*1710mm(Printer) | ||||

| RIP software | MainTopRip6.1/PP | |||

| Weight (with stand) | G.W:1000KG N.W:900KG | |||

| Environmental | Power ON | Temperature: 68° to 90°F (20° to 32°C) (72°F [22°C] or more recommended) / Humidity: 35 to 80% (no conde nsation) | ||

| Power OFF | Temperature: 41° to 104°F (5° to 40°C) / Humidity: 20 to 80% (no condensation) | |||

| Maximum Speed | EPSONDX5 (2H) | EPSON DX5 (4H) | EPSON i3200 (4H) | EPSON i3200 (8H) |

| Draft (2pass) | 65 sqm/h | 130 sqm/h | 160 sqm/h | 280 sqm/h |

| Production(3pass) | 44 sqm/h | 88 sqm/h | 106 sqm/h | 186 sqm/h |

| Quality(4pass) | 34 sqm/h | 68 sqm/h | 80 sqm/h | 155 sqm/h |

| Hi-Quality(6pass) | 28 sqm/h | 56 sqm/h | 52 sqm/h | 100 sqm/h |

| PrintLinks System Requirements | |

| Operating system | Windows® 7/10 (64-bit) |

| CPU | Intel® Core™ 8, 4.0 GHz or faster recommended |

| RAM | 8 GB or more recommended |

| Video card and monitor | A resolution of 1,280 x 1,024 or more recommended |

| Free hard-disk space | 80 GB or more recommended |

| Hard-disk file system | NTFS format |

| Optical drive | DVD-ROM drive |

| Other requirements | Ethernet or USB port |

| Internet connection and web browser to software Registration | |

Special Features

High-speed & High-quality Printing At The Same Time With Xenons Eco Solvent PrinterHIGH-SPEED & HIGH-QUALITY PRINTING AT THE SAME TIME WITH XENONS ECO SOLVENT PRINTER

HIGH-SPEED & HIGH-QUALITY PRINTING AT THE SAME TIME WITH XENONS ECO SOLVENT PRINTER

XENONS is a 3.2m large format Indoor & Outdoor High Quality Eco Solvent Printer.

This printer combines digital printing advantages of high-quality supports 4 Color CMYK or 6 Color YMCK+LM+LC and 8Color options with speeds upto 80-180 sq m /hr.

XENONS is most suitable for a large range of Eco solvent applications like Canvas, SAV, PVC Banner, Backlit Film, Window Film, Fabric ect, indoor & outdoor advertising and decoration industry\

Maximum output speed of 180sqm/h

With its staggered 4 EPSON i3200 printhead, Xenons Coltex X4-320-4H model suitable for any work,

combine a high speed 180sqm/h with high quality 2.5pl. That speed is higher previous EPSON printhead printers.

Mini Jumbo Roll media system

This media system support to load a mini jumbo roll transfer paper about 1500m, Reduces the cost per square meter

and shortens the downtime due to media replacement in comparison to smaller transfer paper rolls.

Auto ink supply system

An automation ink supply system enables you load 10L inks per color, Reduce the running cost and the downtime

due to ink replacement, The ink alarm system helps fill the ink in advance.

An Easy-to-use system

Equipped with automatic capping and cleaning system, minimize the need to call an engineer.

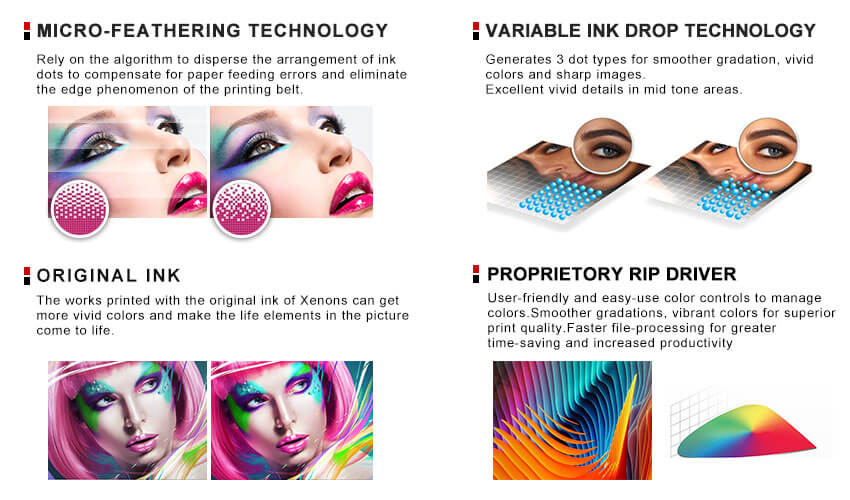

Variable dots printing

Research has shown that the level of grayscale used in an image contribute considerably to its perceived quality,

more so than pure dpi resolution. The larger dots enhanced a superior color, while the smallest dots providing

gradation equivalent to a much higher resolution.

Efficient data algorithm reduce and correct banding

The special data algorithm enable the software analysis the data and reproduce the output method automatically

minimizes ink drying times on substrates, and stepping error compensation, eliminating color banding effects.

Depending on substrates and design, the o-ptimal percentage of feathering can achieve 20~80% speed increases

avoiding the speed reductions caused by adding additional full passes

Intelligent Job management

Print meters setting, printing record management, color mapping function and ink calculation functions

make sure an efficient job management.

Product Images