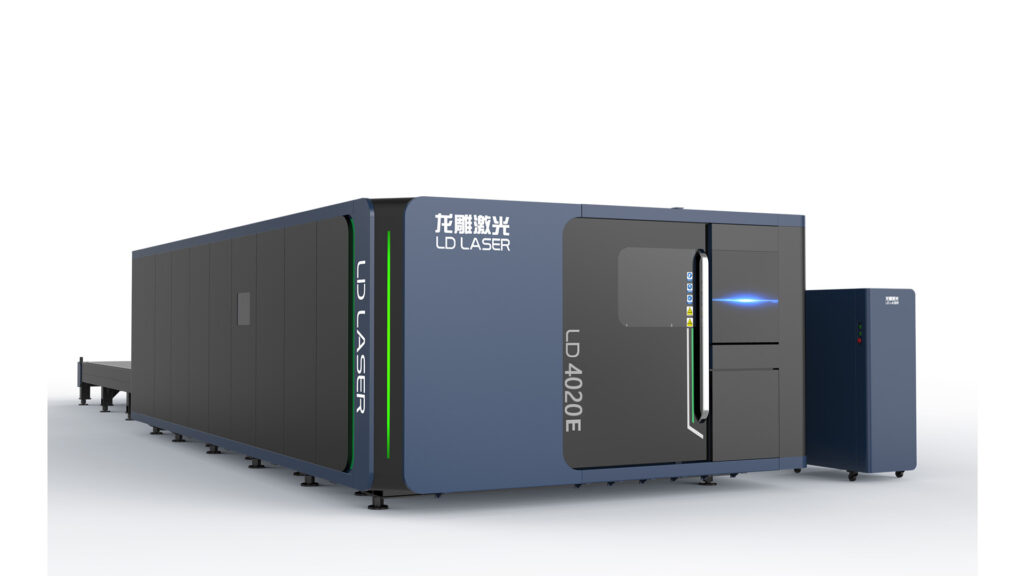

Product Overview

The LD-4020E has a processing capacity of 4000mm×2000mm and features a platform that can be exchanged. The laser power can be adjusted based on the thickness and material of the cutting material, allowing for precise cuts. The fiber laser cutting machine is more efficient and energy-saving when compared to plasma cutting.

Specification (Machine Details)

| Model | LD-4020E |

| Working area | 4000*2000mm |

| MAX linkage speed | 110m/min(1-4kw) 140m/min(≥6kw) |

| MAX acceleration | 1.0G |

| Table load bearing | 2700kg |

| Machine overall dimensions | 11.5m*3.5m*2.4m |

| Overall weight | 13000KGS |

| Positioning accuracy | ±0.03mm |

| Re-positioning accuracy | ±0.02mm |

| Z-axis travel | 150mm |

Special Features

Good cutting quality, reduce labor cost

By utilizing the properties of non-contact laser processing, the laser cutting machine ensures that the workpiece remains undamaged, resulting in a cut product that is free from deformation, burrs, and does not require manual re-grinding.

Save mold investment and reduce production cost

The laser cutting machine is capable of producing different hardware workpieces directly, without requiring the use of molds. This eliminates the need for mold consumption and repairs/replacements, leading to significant savings in processing and production costs. This advantage is particularly beneficial for large product processing

High precision, effectively improve productivity

The laser cutting technique is characterized by precision, flexibility, and high efficiency, making it highly suitable for processing intricate parts. By simply creating a cutting pattern and importing it into the control system, the size of the cut can be adjusted, thereby reducing the product’s manufacturing cycle time. This feature helps to enhance labor productivity during processing and manufacturing.

Fast cutting speed and optimized working environment

The laser cutting machine operates at a high cutting speed, while maintaining stability and producing low levels of noise and dust. Moreover, the machine does not generate any harmful chemicals to the environment or the human body, making it a safe choice for operators. This feature also helps to ensure a clean production site.

Compared to mechanical products, the maintenance costs for a laser cutting machine are relatively low. The laser cutting machine is highly durable, with stable performance and the ability to work continuously without easily becoming damaged. This quality translates to significant advantages in terms of long-term maintenance costs.

Product Images