Product Overview

Best performing cutter in its class

Enhances functions for higher productivity

Improves ARMS5.0 for high precision cutting

Improved application software

Further enhancements to increase usability by innovative new functions

Specification (Machine Details)

| Model | FC8600-60 | FC8600-75 | FC8600-100 | FC8600-130 | FC8600-160 |

|---|---|---|---|---|---|

| CPU | 32-bit CPU | ||||

| Configuration | Grit rolling type | ||||

| Drive method | Digital servo drive | ||||

| Max. cutting area (W x L) (*1) | 610 mm x 50 m | 762 mm x 50 m | 1067 mm x 50 m | 1372 mm x 50 m | 1626 mm x 50 m |

| Cutting area of guaranteed accuracy (*2) | 590 mm x 15 m | 742 mm x 15 m | 1043 mm x 10 m, 894 mm x 15 m | 1342 mm x 10 m, 894 mm x 15 m | 1603 mm x 10 m, 894 mm x 15 m |

| Mountable media width | Min. 50 mm Max. 770 mm |

Min. 50 mm Max. 920 mm |

Min. 50 mm Max. 1224 mm |

Min. 50 mm Max. 1529 mm |

Min. 50 mm Max. 1850 mm |

| Max. cross cut width | 734 mm | 886 mm | 1191 mm | 1496 mm | 1750 mm |

| Number of push rollers | 2 rollers | 2 rollers | 3 rollers | 3 rollers | 4 rollers |

| Max. cutting speed | 1485 mm/s at 45° direction | ||||

| Axial acceleration | Max. 39.2 m/s2 (4 G) in 8 steps | ||||

| Cutting force | Max. 5.88 N (600 gf) in 48 steps | ||||

| Mechanical resolution | 0.005 mm | ||||

| Programmable resolution | GP-GL: 0.1 / 0.05 / 0.025 / 0.01 mm, HP-GL™: 0.025 mm | ||||

| Distance accuracy (*2) | Max. 0.1 mm or 0.1 % of plotted length | ||||

| Repeatability (*2) | Max. 0.1 mm in plot up to 2 m (excluding the expansion and contraction of the media) | ||||

| Minimum character size | Approx. 3 mm alphanumeric (varies depending on character font and media) | ||||

| Mountable number of tools | 1 tool (cutting blade, plotting pen or pouncing tool) in standard; 2 tools (cutting blade and plotting pen) when second penholder (optional) is installed |

||||

| Blade types | Supersteel (0.9 mm or 1.5 mm diameter) | ||||

| Pen types | Water-based fiber-tip pen, Oil-based ballpoint pen | ||||

| Pouncing tool type | Steel pin 1.2 mm diameter, required optional pouncing tool (PPA 33-TP12) | ||||

| Media types (*3) | Self-adhesive marking film (vinyl, fluorescent, reflective, high-intensity reflective film) up to 0.25 mm thick, Sandblast resist rubber up to 1 mm thick |

||||

| Compatible paper for pouncing | Regular paper from 0.06 to 0.13 mm thick | ||||

| Light pointer | Built into the tool carriage | ||||

| Cross-cutter | Built into the tool carriage | ||||

| Perforation cutting | Supported (performed by force control) | ||||

| Registration mark sensing system | Scans the mark by optical sensor (ARMS5.0), Segment area and Multiple-mark compensation, 4-points axis alignment, Auto mark detect | ||||

| Standard interface | USB2.0 (High speed), RS-232C, and Ethernet (10BASE-T/100BASE-TX) | ||||

| Buffer memory | 2 MB | ||||

| Command sets | GP-GL / HP-GL™ emulation (Set by menu or command, and selects from GP-GL, HP-GL™, or Auto select) | ||||

| Condition settings | Dual configuration (save two (2) user settings with eight (8) separate condition setting for each user) | ||||

| Display | Graphic type LCD (3-inch, backlight) | ||||

| Power source | 100 V to 240 V AC, 50 / 60 Hz | ||||

| Power consumption | Max. 160 VA | ||||

| Operating environment | 10 to 35 °C, 35 to 75 % R.H. (non-condensing) | ||||

| Guaranteed accuracy environment | 16 to 32 °C, 35 to 70 % R.H. (non-condensing) | ||||

| External dimensions (W x D x H) | Approx. 1128 x 715 x 1219 mm | Approx. 1278 x 715 x 1219 mm | Approx. 1578 x 715 x 1219 mm | Approx. 1878 x 715 x 1219 mm | Approx. 2138 x 715 x 1219 mm |

| Weight | Approx. 38 kg including stand |

Approx. 42 kg including stand |

Approx. 46 kg including stand |

Approx. 50 kg including stand |

Approx. 59 kg including stand |

| Included software (*4) | Windows driver, Plotter controller, Graphtec Pro Studio (*5) (*6), Cutting Master 4 (*6), Graphtec Studio for Mac |

||||

| Compatible OS (*4) | Windows 10 / 8.1 / 8 / 7 Mac OS X 10.7 to 10.11 / macOS 10.12 (Sierra) to 10.14 (Mojave) |

||||

| Compatible Standards | UL60950-1, cUL, CE mark (Low voltage and EMC), KC mark (Low voltage and EMC) | ||||

| FCC-A, EN55022-A | |||||

Standard accessories

| Item | Q’ty | Description | |

|---|---|---|---|

| Power cord | 1 | The type of cord is different by destination | |

| Cutting blade holder | 1 | PHP33-CB09N-HS | |

| Cutting blade | 1 | CB09UB | |

| Fiber-tip pen holder | 1 | PHP31-FIBER | |

| Water-based fiber-tip pen | 1 | KF700-BK (black ink) | |

| Stand | 1 | Parts kit of stand | |

| Media stocker | 1 | Set of stock rollers and mounting brackets (Installed on the stand) | |

| Basket | PG0039 | 1 | Parts kit for FC8600-60 |

| PG0040 | Parts kit for FC8600-75 | ||

| PG0041 | Parts kit for FC8600-100 | ||

| PG0042 | Parts kit for FC8600-130 | ||

| PG0043 | Parts kit for FC8600-160 | ||

| USB cable | 1 | Cable for USB2.0, 2.9m long | |

| DVD-ROM | 1 | User manual (PDF format), Windows driver, Software (Plotter controller, Graphtec Studio, Cutting Master 3) | |

| Manual | 2 | Quick start and safety guide | |

Options

| Item | Part No. | Description |

|---|---|---|

| Additional Media Stocker | RSK0020 | For FC8600-60 (Stock roller, bracket) |

| RSK0021 | For FC8600-75 (Stock roller, bracket) | |

| RSK0022 | For FC8600-100 (Stock roller, bracket) | |

| RSK0023 | For FC8600-130 (Stock roller, bracket) | |

| RSK0024 | For FC8600-160 (Stock roller, bracket) | |

| 2nd pen holder | ECK0009 | For dual tool configuration (dealer option) |

| Flange | OPH-A21 | Flange for media holding |

| Additional Push Roller | OPH-A22 | One additional push roller |

| Graphtec Pro Studio Plus | OPS682-PLS | Design software including all advanced functions. (1 license) |

| Graphtec Pro Studio Plus for Rhinestone | OPS682-RSF | Limited edition of rhinestone function only. (1 license) |

| Graphtec Pro Studio Plus for Auto Nesting | OPS682-ANF | Limited edition of auto nesting function only. (1 license) |

Supplies

| Item | Part No. | Description | Package |

|---|---|---|---|

| Cutting blade holder | PHP33-CB09N-HS | For CB09U series blade | 1 set/pack |

| PHP33-CB15N-HS | For CB15U series blade | 1 set/pack | |

| PHP35-CB09-HS | For CB09U series blade | 1 set/pack | |

| PHP35-CB15-HS | For CB15U series blade | 1 set/pack | |

| Cutting blade | CB09UB-5 | 0.9mm dia. 45º angle, Supersteel | 5 blades/pack |

| CB09UB-K60-5 | 0.9mm dia. 60º angle, for thin film | 5 blades/pack | |

| CB15U-5 | 1.5mm dia. 45º angle, supersteel | 5 blades/pack | |

| CB15U-K30-5 | 1.5mm dia. 30º angle, for sandblast rubber | 5 blades/pack | |

| CB15UA-5 | 1.5mm dia. 45º angle, for high intensity reflective film | 5 blades/pack | |

| CB15UA-K30-5 | 1.5mm dia. 30º angle, for high intensity reflective film | 5 blades/pack | |

| Cross-cutter blade | CT01H | Standard type | 1 blade/pack |

| CT02U | High durability type | 1 blade/pack | |

| Water-based fiber-tip pen, and pen holder | KF700-BK | Pen (black) | 10 pens/pack |

| KF700-RD | Pen (red) | 10 pens/pack | |

| PHP31-FIBER | Pen holder for KF700 series pen | 1 set/pack | |

| Oil-based ballpoint pen, and pen holder | KB700-BK | Pen (black) | 10 pens/pack |

| PHP34-BALL | Pen holder for KB700 pen | 1 set/pack | |

| Pouncing tool | PPA33-TP12 | Steel pin 1.2 mm dia. | 1 set/pack |

Special Features

Best performing Cutter in its class

FC8600 series is premiere cutting plotter providing higher productivity and greater ease of use

Fastest cutting speed in its class

1485 mm/s maximum cutting speed for the higher productivity.

Highest cutting force in its class

5.88 N (600 gf) maximum cutting force for a wide variety of applications. Expands the range of possible cutting media such as thick film.

Reliable long-length tracking

Guaranteed 15m tracking and accuracy. (*1)

Includes basket and push rollers with 3 different pressure settings (*2) to provide a more stable media feed and to support a wider range of media.

(*1) Operated with Graphtec specified media and conditions.

(*2) The center push rollers have 3 pressure settings, the end push rollers have two pressure settings.

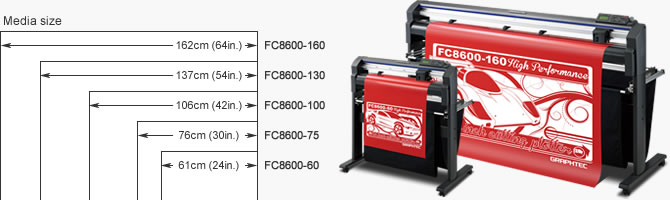

Five sizes to match all requirements

The series includes cutting widths of 61 cm (24 in.) to

162 cm (64 in.).

Enhanced functions for higher productivity

The enhanced features improve your work efficiency and increases productivity.

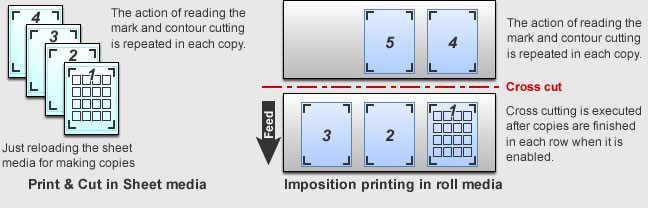

Copy with ARMS

It supports the copying of the cutting data including the ARMS control command for making multiple copies of the downloaded data. This allows multiple copies to be created without a PC, significantly improving work efficiency. The media can be also separated by each row with the cross cutter when the cross cut function is enabled. It provides high-productivity and highprecision print & cut.

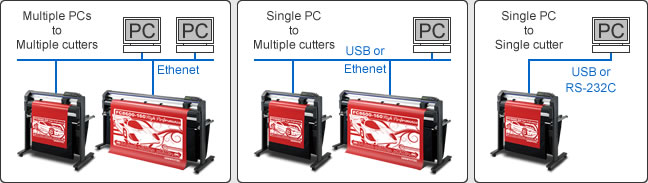

Built-in network interface

The USB 2.0 (High Speed), RS-232C and Ethernet (10BASE-T/100BASE-TX) are built in as standard. Multiple interfaces enable various connections such as a single PC to single plotter and multiple PCs to multiple plotters. The Ethernet connection also allows sharing of the cutter over a network.

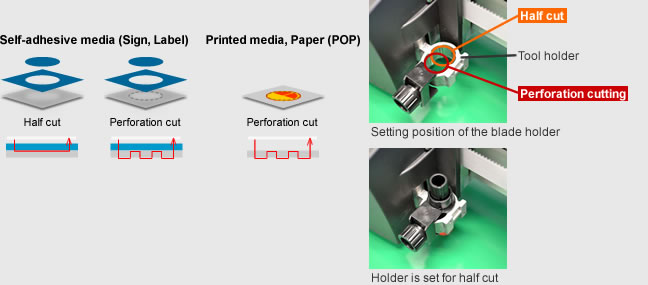

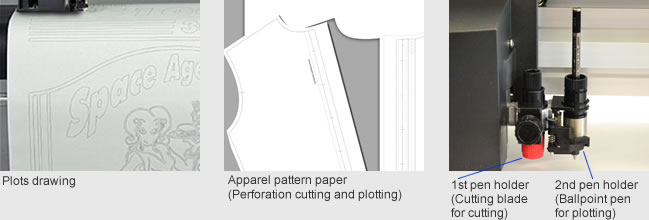

Perforation Cutting

Perforation cutting is performed by controlling the cutting force instead of blade up/down movements, increasing throughput. This is perfect for cutting separation lines for tearing out labels, fold lines for POP signs, and others.

Auto-paneling

Auto-paneling is a new feature that automatically splits long-length jobs into smaller pages that are cut sequentially but without any gaps. The result is a seamless, long-length finished job. Media movement is limited to the smaller page being cut, improving accuracy and tracking.

Intuitive operation

Settings can be easily set up using the large 3-inch LCD and tactile control panel. It is icon driven and supports multiple languages.

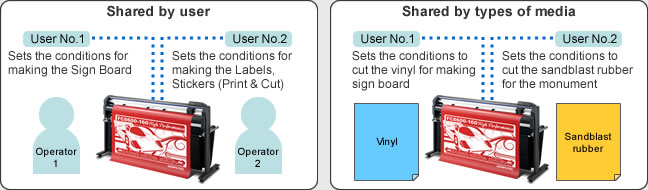

Dual configuration

Save two (2) user settings with eight (8) condition settings for each user. A fast access key allows quick switching between users. One cutter can be shared by multiple users or for multiple purposes.

2 tools configuration for cutting & plotting (Option)

It holds both a pen for plotting and a blade for perforated cutting. The tool is automatically switched for cutting and plotting as needed.

Product Images