Product Overview

5.0m Hybrid printer

Print Size:5000mm

Colors: CMYK, White,LcLm

Printhead: KONICA KM1024I/KYOCERA KJ4A

Print Speed: Up to 200 ㎡/hr

1.High performance linear motor

2.Anti-crash Sensor, Resume print after E-stop

3.Vacuum Convey-belt System

4.Industrial Take up & Feeding System

5.Belt automatic deviation correction Function

6.Auto ink volum alarm system

7.Anti-static Bar

Specification (Machine Details)

FR5000 uv Hybrid printing Machine

Model: FR5000

Printing Size: 5.0m

Media Thickness: 5 mm.

Ink Type: UV Ink(Medium/Flexiable)

Curing System: UV LED(water cooling)

Rip Software: Sai/ ONYX/Caldera

Print Head control: Temperature and Valtage control by Waveform

Operation Environment: Temp. 20℃-28℃; Humidity 40%-60%

Power Supply: 50/60Hz 220V(10%) > 30A Single PHase

Image Outdoor Lifespan: 3 Years(Base on DOCAN Ink)

Dimention: 7650x1576x1465mm; 4200Kgs; Iron frame base. No wood pack

Warranty: 12 months after installation

General Information

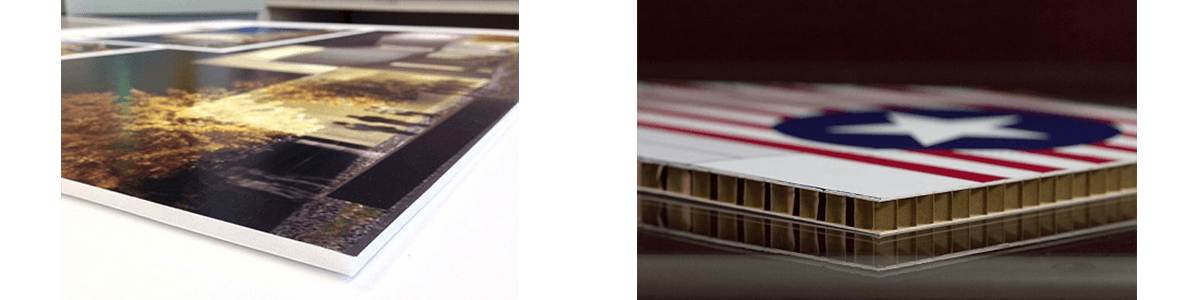

FR5000 UV Hybrid printer is a huge heavy duty belt-conveyed UV printing machine, which is designed mainly for both roll to roll printing and board sheet printing. 5m width offers a solution of multiple smaller sized media to print at the same time. With extension tables at the back and front, they can print unlimited length of rigid and flexible medias thanks to the vacuum belt feeding and conveying system.Using the UV ink they can print excellent images on various rigid medias, such as glass, acrylic, wood, PVC foam board, KT board, polycarbonate, MDF, aluminium, cellphone case, ceramic tiles, and flexbilematerials like banners, vinyl, mesh, and so on.Also, they offer various ways of printing the white color, and can print the three-layer spot colors which means printing color-white-color at one time. The printhead options are Konica Minolta 1024i 6-13pL and KyoceraKJ4A 4pL . The printing colors are Lc Lm Y M C K , White is optional!

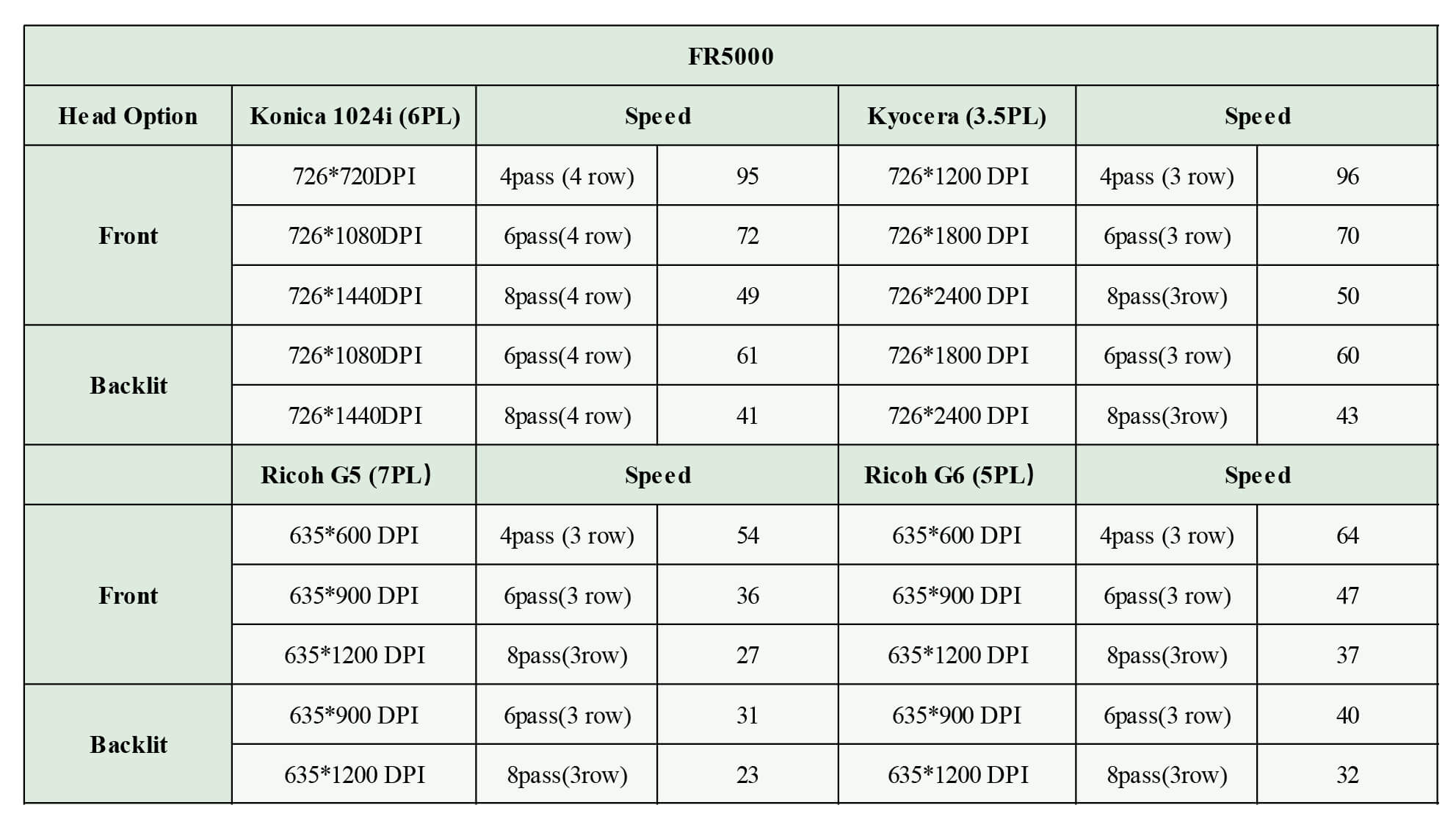

Speed

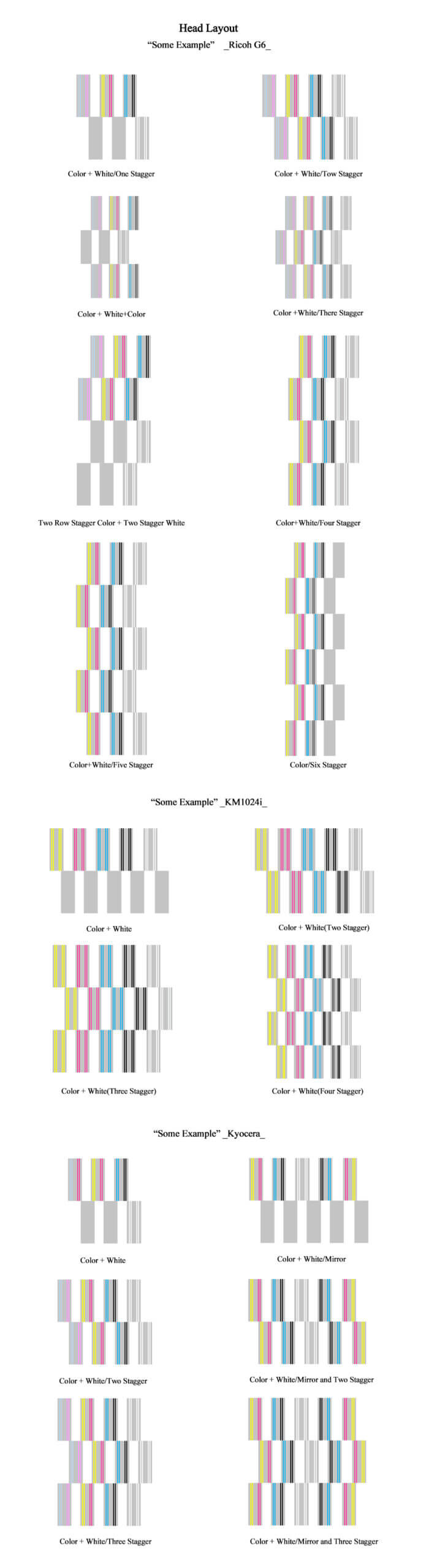

Head Layout

Print Head Options

Technical Parameter

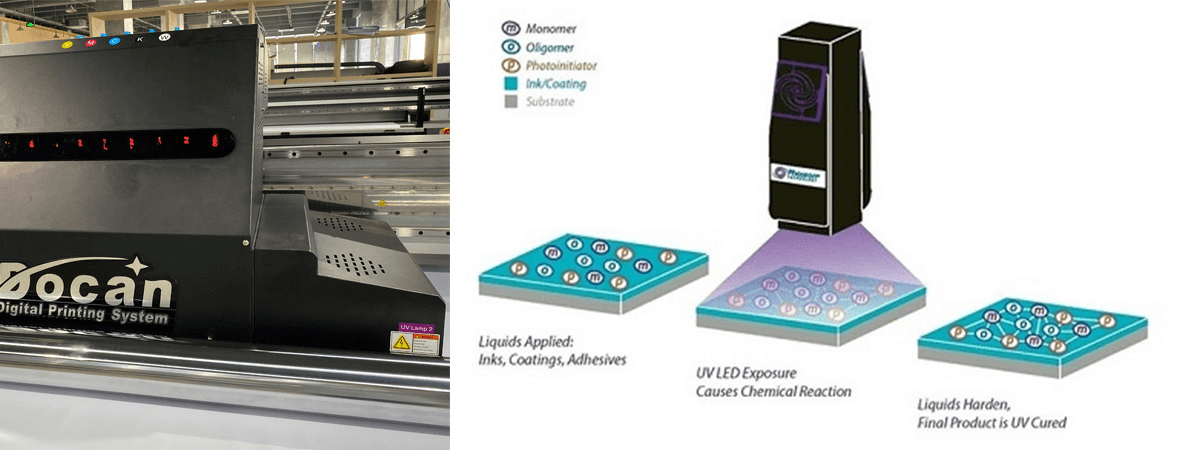

Ink Curing System

Ink curing system operates with water-cooled Led UV lamps which has longer life time, more silent operation, do not make ozonic gas and emit less heat than traditional mercury lamps. It enables user to print on wider media choices,printings on sensitive or non-sensitive materials as well as to save energy,costs and time. Excluding the use of VOC (Volatile Organic Compounds) the UV curable ink is environmental friendly and has no bad smell. Drawer-type UV lamp cassette makes easy to replace the lamps when needed.

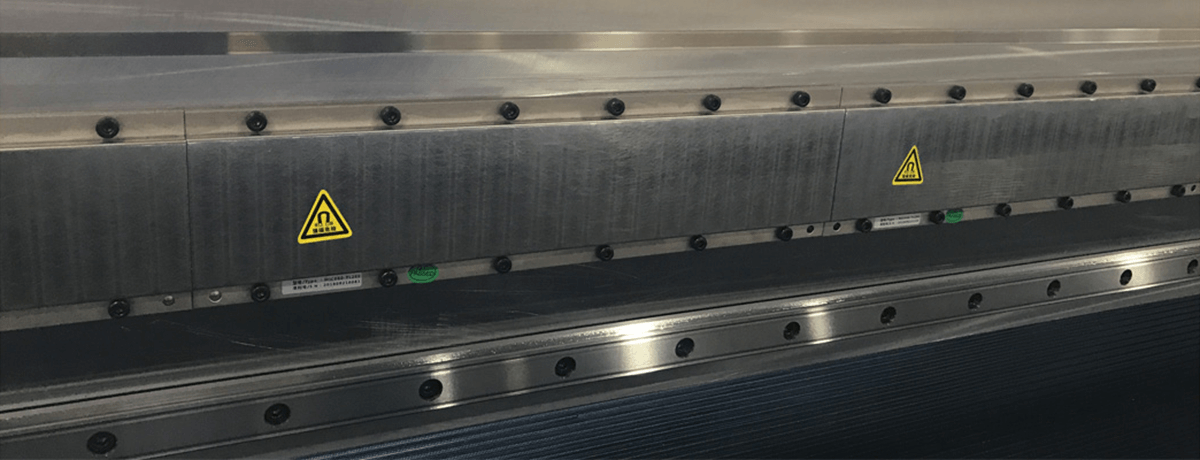

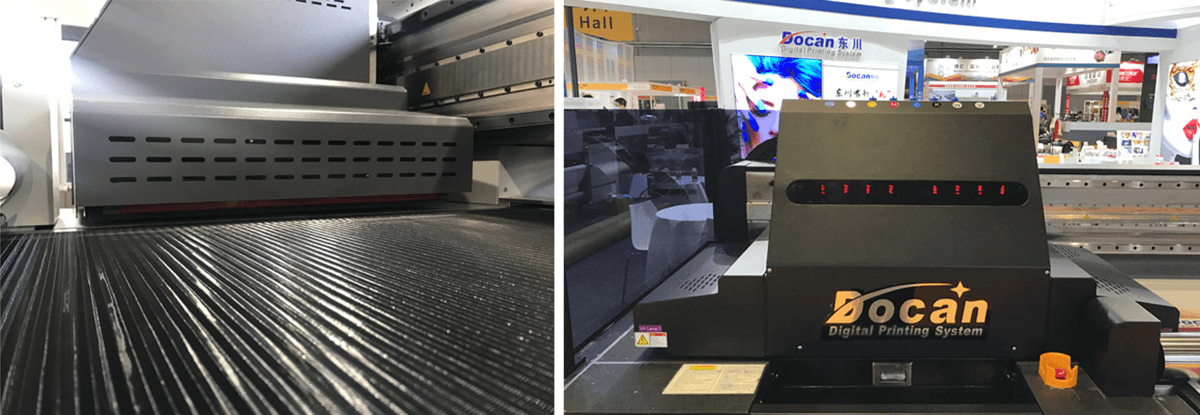

Vacuum Belt Table

The FR5000 Hybrid UV printer installed with 5.0m Belt-convery feeding system, with a unaverage vaccum zone design, which makes posibility of different size media printing and max 5000mm. The Belt is driven by High Precision HARMONIC Reducer motor to ensure the motion stability of the media feeding step.

MAGNETIC GUIDE RAIL

Equipped with Japanese THK silent double guide rail with X axial metal raster and beltless magnetic system which ensures straight carriage moving to achieve accurate printing.

PRINTHEAD TRANSPORT SYSTEM

Thanks to the high-precision impact sensors on both sides of the head transport mechanism, the print heads are not damaged from curled, swollen or surged materials.The mechanism has anti-static devices to prevent electrostatic effect that disrupts the image quality.

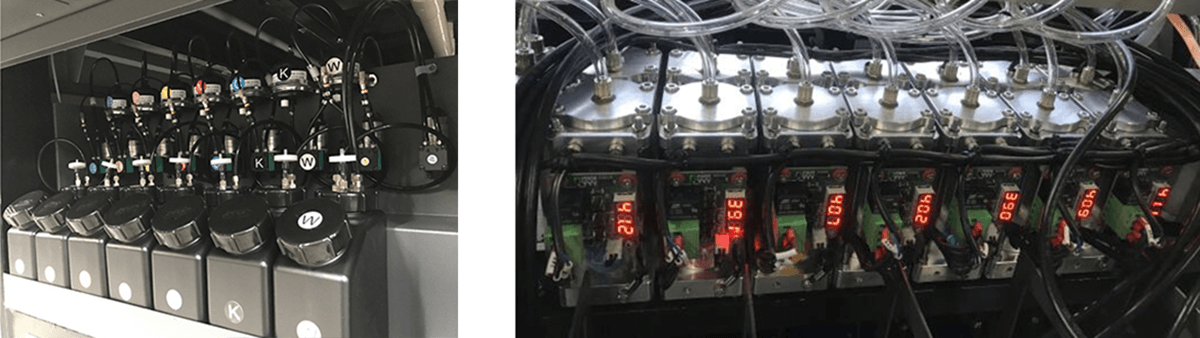

Ink Supply Unit

Automatic high-volume Ink Supply system ensures continuous printing. The white ink has automatic stirring and circulation system, which avoids the clog of the white printhead. The system continuously circulates the ink between the Sub Ink Tank and Main tank; internal main tank. It equipped with Ink low level sensor, gives alarm once ink level below than setting.

Direct Printing

Can print on up to 50mm thick substrates and the printing distance between the table and printhead can be raised more up to 50mm with an optional adaptor to print on thicker materials. It is possible to print heavy substrates up to 200kg weight.

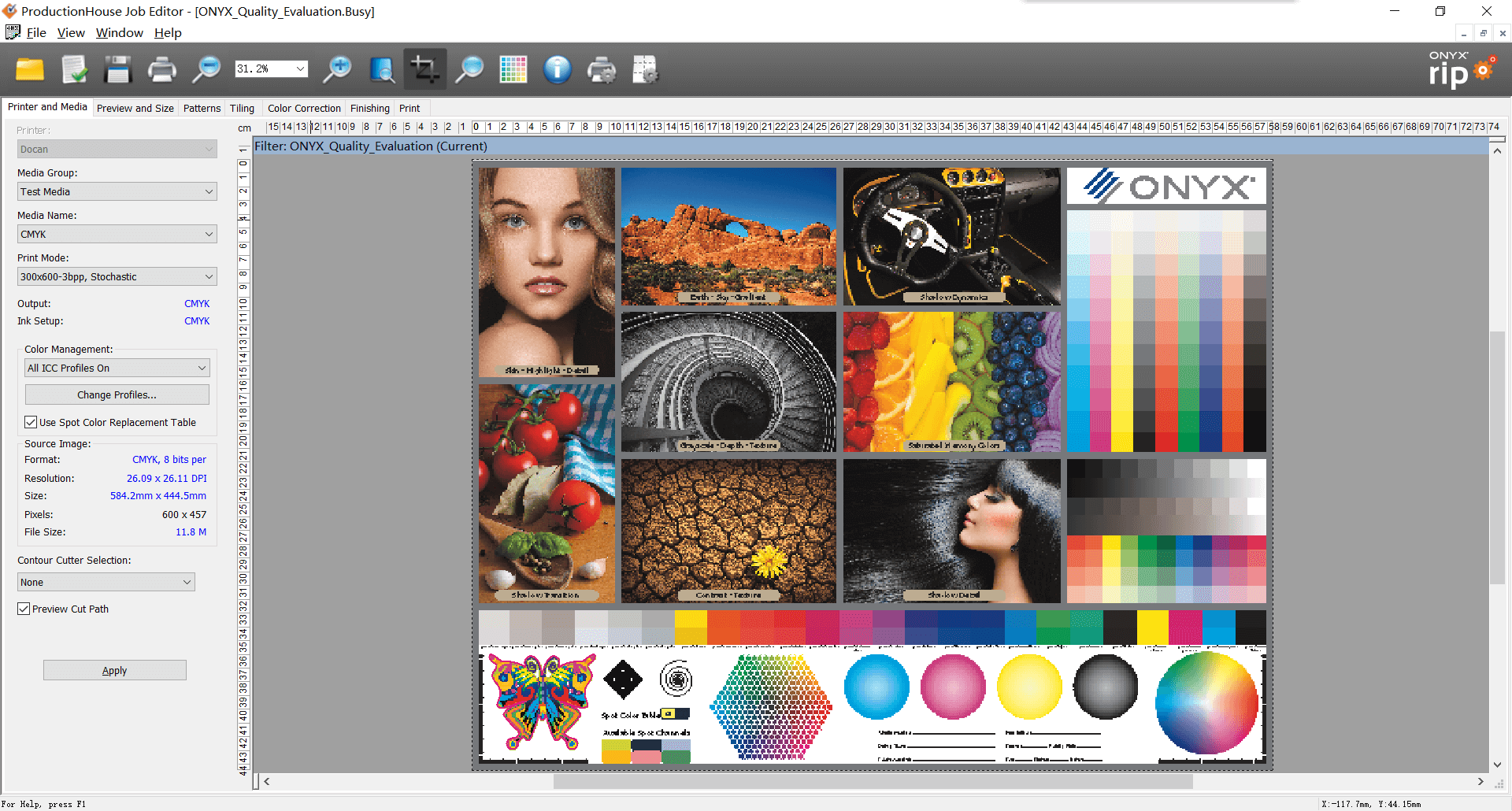

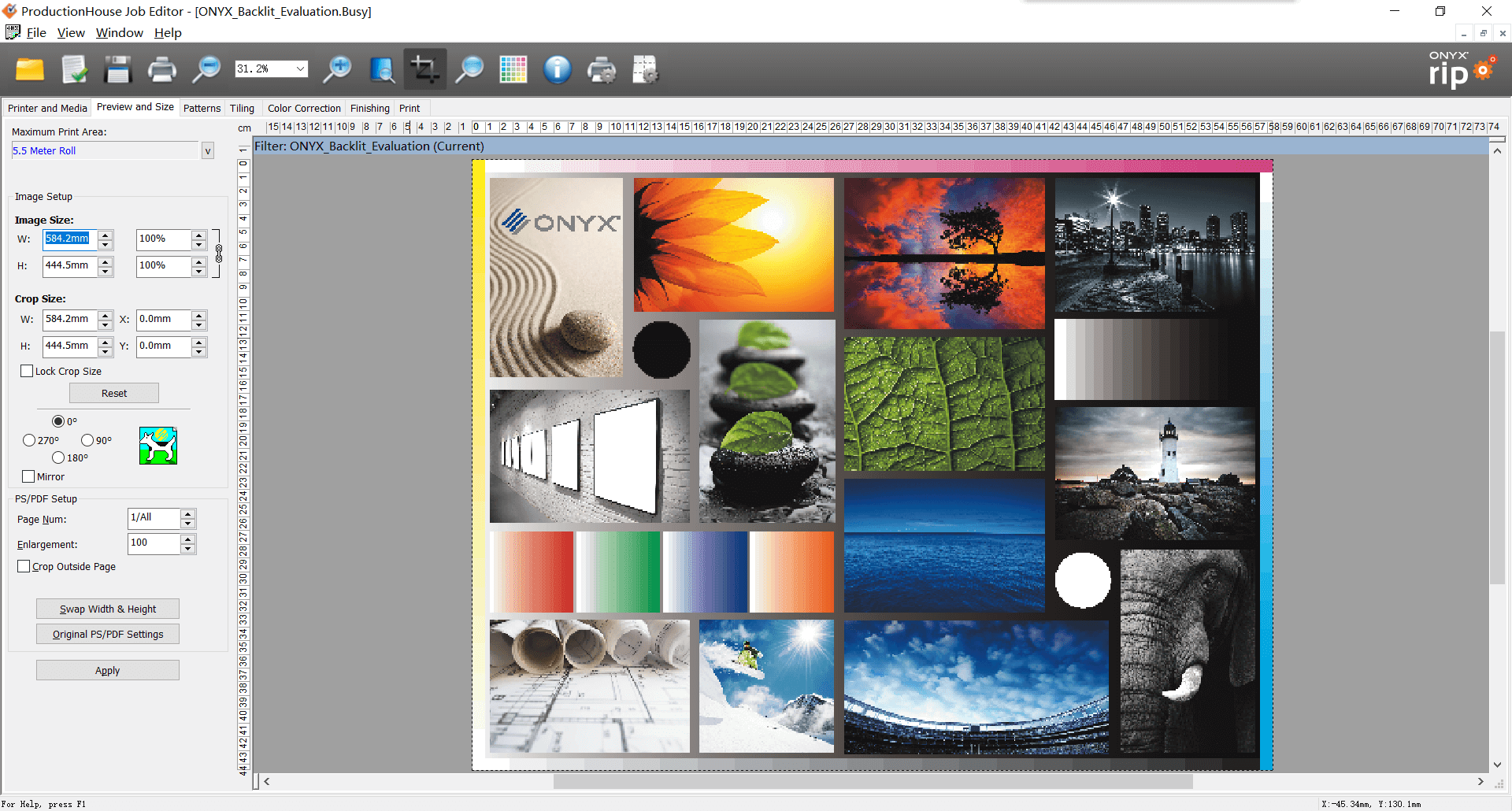

Rip Software

ONYX RIP Center is standard software with Kyocera engine, which provides the control and simplicity needed to get started in wide format print production and achive consistent high-quality output. The versatile tools in ONYX RIP Center software make it easy to prepare jobs and produce sellable prints faster.

With advanced RIP technology, the user can get smooth gradients, vivid images and sharp small size text. The ICC color management workflow provides vibrant and bright colors.

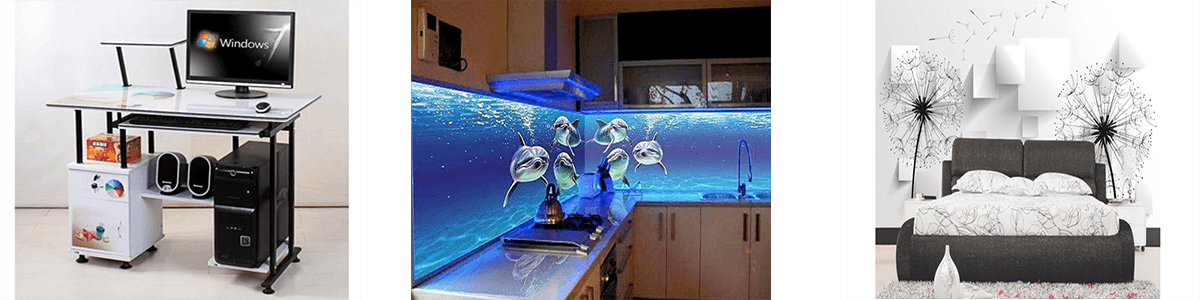

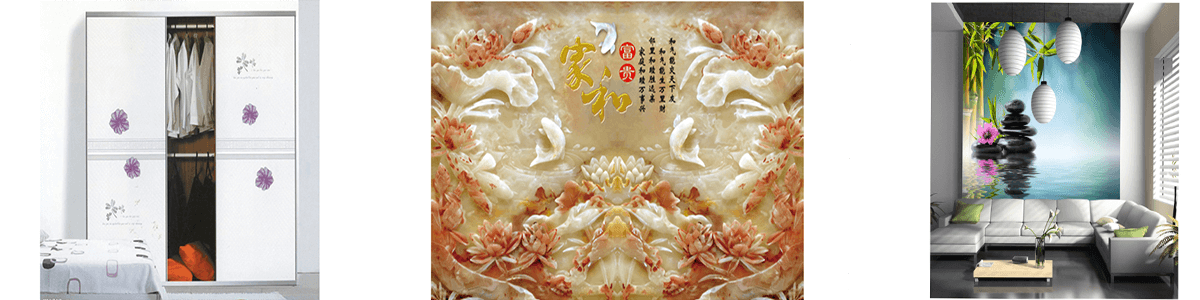

Example Applications

DOCAN · Shanghai

Since 2005

Product Images